Because your project deserves more: Our services go beyond the standard

Our supplementary services create real added value: from digital project management and sustainability consulting to operational optimization - we support you throughout all project phases.

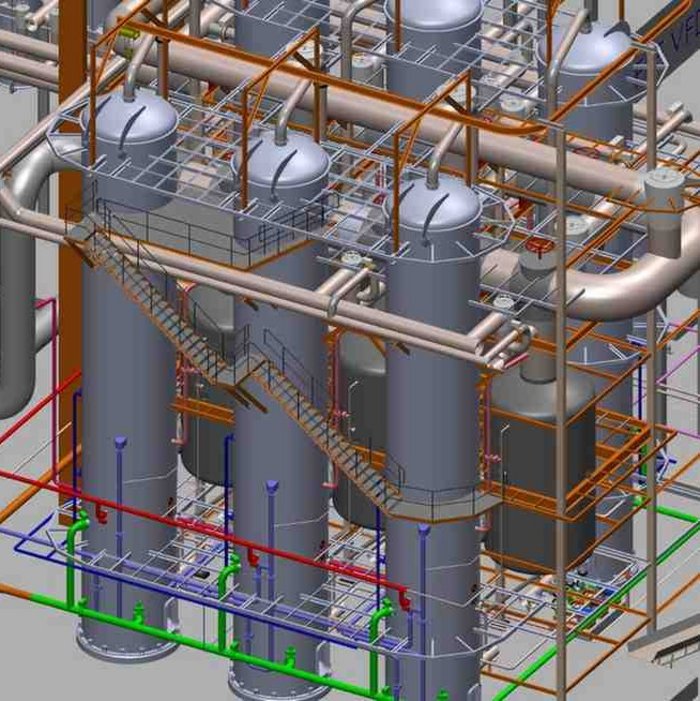

EPCM

With our EPCM approach, we bundle engineering, procurement and construction management into an efficient overall process. Supplementary services such as approval management or commissioning ensure the highest level of planning depth and project transparency - from a single source.

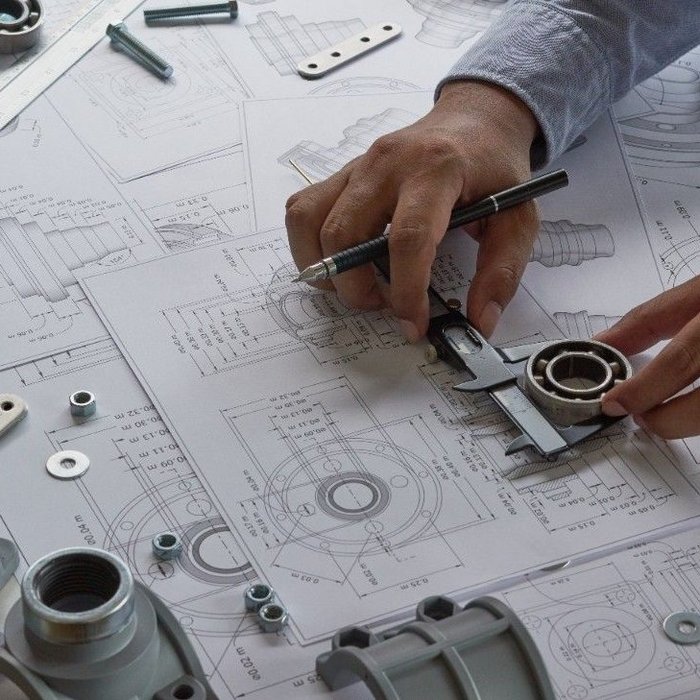

Basic engineering - a solid foundation for your project

In basic engineering, we lay the foundation for project success: with reliable concepts, initial designs, cost estimates and schedules. We create planning security, identify risks at an early stage and prepare the next project phase in the best possible way.

Detail engineering - precise. well thought out. realizable.

In detail engineering, we transform concepts into concrete, ready-to-implement solutions: with complete plans, parts lists, specifications and interface coordination. In this way, we create the conditions for smooth procurement and implementation on site.

Safety in industrial plants - reliable & standard-compliant

Safety is no coincidence: we integrate customized safety concepts into every phase of your system - from planning to operation. Whether explosion protection, functional safety or risk assessment according to HAZOP - we ensure standard-compliant implementation and maximum operational safety.

Efficient construction management for your projects

We manage your construction site with experience, vision and technical precision. Our construction management ensures smooth processes, coordination of all trades and compliance with costs, deadlines and quality - for maximum safety and project success on the construction site.

Digital plant documentation - fast, secure, networked

Paper is a thing of the past: with ENCOS, you can rely on digital plant documentation that noticeably improves access, management and efficiency. Whether archiving, system integration or mobile use - we make your documentation future-proof, flexible and legally compliant.

EI&C engineering for safe and efficient systems

Whether energy supply, automation or process safety - our EI&C planning integrates seamlessly into your systems. From concept development to commissioning, we deliver sophisticated solutions for measurement and control technology - compliant with standards and reliable in operation.

Process technology from a single source

We combine process engineering and process technology to create integrated solutions - from the initial idea to implementation in your plant. With sound analysis, innovative concepts and practical planning, we optimize material flows, energy use and process reliability in the long term.

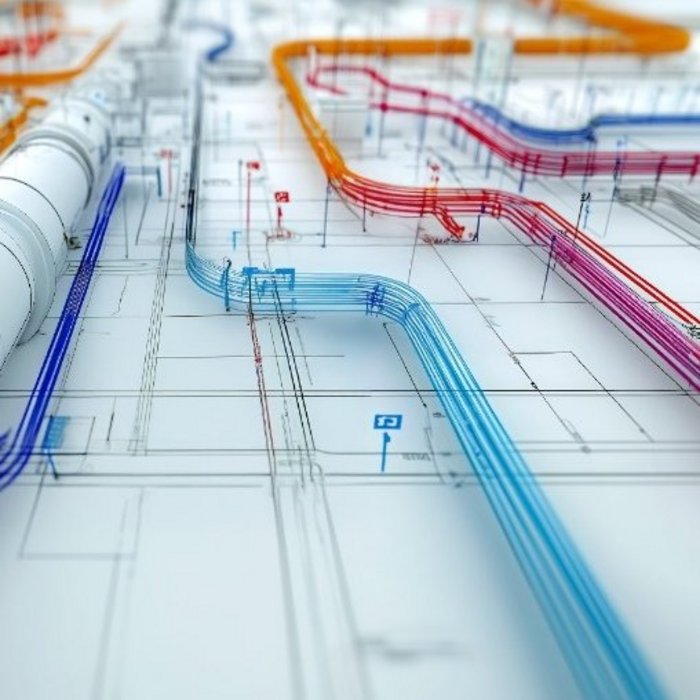

Piping engineering for safe and efficient systems

From the route to the isometry: we plan pipelines precisely, economically and in compliance with regulations. Whether new planning, conversion or revamp - our piping team masters all standards, materials and media. 3D planning, stress analysis and ease of installation included.

Feasibility studies with Aspen - sound & resilient

With Aspen tools, we analyze the technical and economic feasibility of your process engineering concepts at an early stage. Whether material flow simulation, energy efficiency or scale-up - we provide a reliable basis for decision-making on investments, optimization and project design.

Mechanical engineering - integrated, precise, process-orient

Whether rotating devices or static equipment: our mechanical engineering ensures durable, maintenance-friendly and process-integrated solutions. In close coordination with process engineering, I&C and electrical engineering, we plan robust, ATEX-compliant and efficient solutions - right up to the specification stage.

Civil engineering - integrated into your system planning

Whether foundation statics, steel construction, pipe route planning or 3D laser scanning: Our civil engineering is fully integrated into the system planning. We think about trades together, secure interfaces and deliver reliable foundations - ideal for EPCM projects and complex conversions.

Authority Engineering – Approval-Ready from Day One

Whether BImSchG, WHG, AwSV or Hazardous Incident Ordinance – we develop approval-ready projects and integrate all requirements right into your planning. From application and condition management to safety analysis: interdisciplinary, legally compliant, and perfectly aligned with the authorities.

Project management for all phases of your plant projects

Whether new construction, expansion, conversion or modernization - we manage your project in a structured, efficient and flexible manner. With clear organization, deadline and cost control, technical expertise and interdisciplinary coordination, we ensure planning security and sustainable project success.

Operator obligations under control

Technical regulations, inspection deadlines, liability: We support you in fulfilling your operator obligations - from risk analysis and compliance strategies to training. Together with the TÜV NORD GROUP, we identify weak points and create legally compliant, sustainable structures.