Detail Engineering

Our detail engineering includes all relevant engineering procedures and planning steps up to commissioning of the process plant, if required also as part of an EPCM project.

What exactly does Detail Engineering involve?

The biggest contribution to the project’s duration is made by the detail engineering phase. As in all cases, the scope and complexity of detail engineering activities essentially depends on the type and size of the project. The most important working points during the detail engineering are:

- Final determination of the basic engineering

- Process engineering design of the apparatus including strength calculations

- Preparation of technical specifications

- Pipeline planning & statics

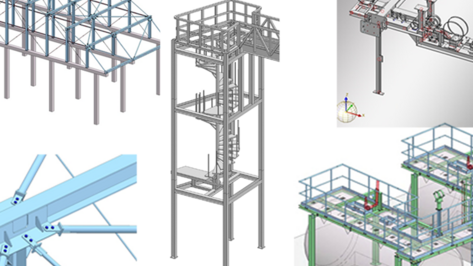

- Steel construction & statics

- EI&C technology

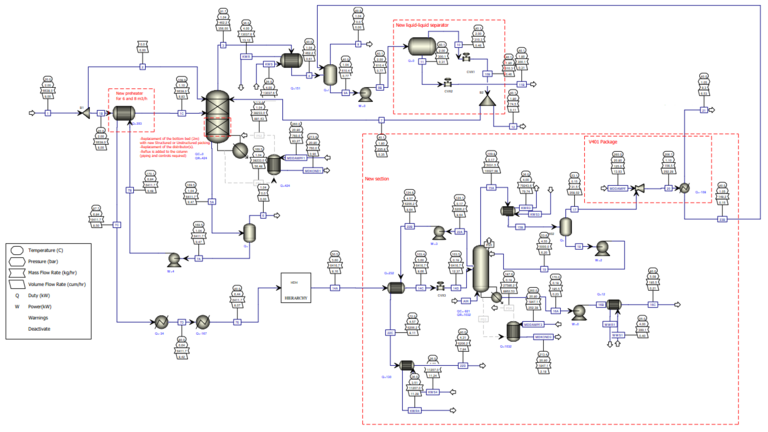

- P&ID flow charts

- Installation planning

- Documentation

What are these tasks in detail?

Detailed planning is a highly multidisciplinary process that involves many specialists whose goal is to complete in detail, fix and establish package plans for all the requested units. The variety of activities in the planning area should not be underestimated.

Many documents in the detailed planning phase cannot be processed independently of each other. Piping isometrics, for example, can only be finalized once the piping plans are available. Piping plans can only be finalized when the final layout, the piping and instrument flow diagrams as well as the corresponding pipe route plans are submitted. The specific nominal diameters in the piping and instrument flow diagrams require the hydraulic design to be carried out. Finally, when new documents are created, additional changes may occur for documents that already exist, which in turn are essential for the creation of new documents.

The planning results of this engineering phase are handed over to the procurement process in the form of tender and inquiry documents with defined specifications for all technical equipment and materials required for the construction of the process plant, including assembly services. The services of basic and/or detail engineering can also be requested separately from DMT ENCOS. We always collaborate with you in a customized way that suits your individual needs.

- All-inclusive service from a single source

- Short-term processing of your project enquiries

- Solution-oriented and state of the art