Process Safety / Process Safety Technology

DMT ENCOS supports you with safety issues that may arise throughout the entire life cycle of a technical system. A holistic approach which takes into account legal regulations and safety requirements is a very special area of expertise in the field of chemicals, oil and gas. In cooperation with the operator and the involved authorities, we develop the appropriate safety concept for you or support you individually with safety analysis and according to the current state of the art.

As an independent third party, DMT ENCOS carries out special risk analyses and legally required inspections to your plants together with our colleagues from TÜV NORD Group, thus providing optimization proposals and the necessary support in this specialized area. Our process engineers support you and your project right from the planning phase in order to guarantee safety and efficiency of your plant.

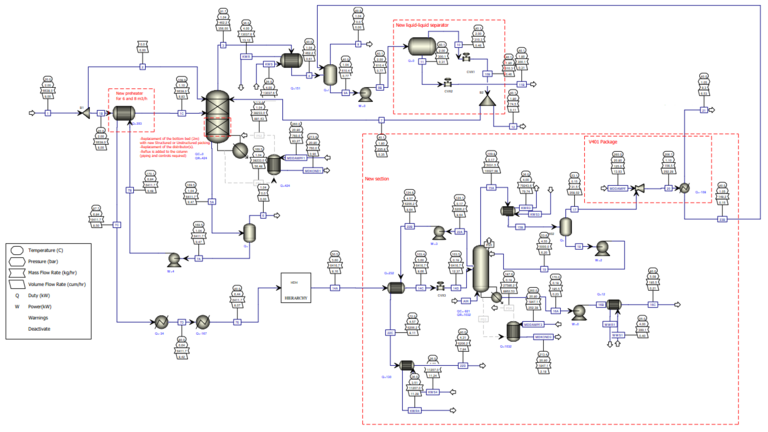

In general, with existing process engineering processes, we first carry out of what is known as safeguarding. This is a safety analysis that focuses on avoiding unacceptably high operating pressures, operating temperatures or other dangerous system conditions. We also examine individual processes and analyze them for possible weak points and compare them with requirements from technical rules for operational safety or technical rules for hazardous substances with special plant reference according to your on-site situation.

Our holistic Approach:

If, due to the product used, it is a sensitive process plant and subjected to the Major Accidents Ordinance, DMT ENCOS can carry out individual safety analysis, e.g. HAZOPs, together with you. This standardized procedure can be implemented as a project within the framework of multidisciplinary workshops.

Any additional expert opinions required in connection with safety analyses can be provided at any time as an additional service from the service portfolio of the TÜV-NORD Group.

DMT ENCOS Services:

- Safeguarding Report

- HAZOP report

- Cause and Effect Matrix of the safety shutdowns

- Cadaster of safety fittings with blow-off scenarios

- Preparation of data sheets for the safety fittings / safety instrumentation

- Design documents of the blow-down system components according to API 520/521

Our Services for Your Process Safety

We are looking forward to your inquiry.

Buxtehuder Straße 29

D-21073 Hamburg

Tel.: +49 40 751158-0

Fax: +49 40 751158-30

info@encos.de