We also deal with special topics that not everyone dares to tackle with.

Overview of Our Services

Saving operating costs through energy optimization

As a TÜV NORD GROUP company, we have many years of experience in the planning and construction of process plants for customers from the chemical and petrochemical, petroleum, pharmaceutical, energy and environmental sectors. DMT ENCOS covers the entire planning chain, from process development and study including simulation and balancing of processes from basic engineering to detailed planning with subsequent site support.

In recent years, the development of innovative solutions for energy optimization and energy efficiency increase has become increasingly important in the DMT ENCOS portfolio. For example, an energy efficiency project was developed and implemented on behalf of a client in which steam and cooling water consumption has been substantially reduced and energy costs by means of heat recovery in a stripping plant were saved.

Customer / Problem definition

The client from the chemical industry produces organic and inorganic chemicals in one of its plants. For a planned capacity expansion of a process plant, the existing utility systems have reached their capacity limits. Due to insufficient steam and cooling water supply, a complex expansion of the corresponding systems was highly likeable. This had to be averted - with the additional goal of reducing the consumption of cooling water and steam through process optimization leading at the same time to reduced energy costs.

Process engineering solution

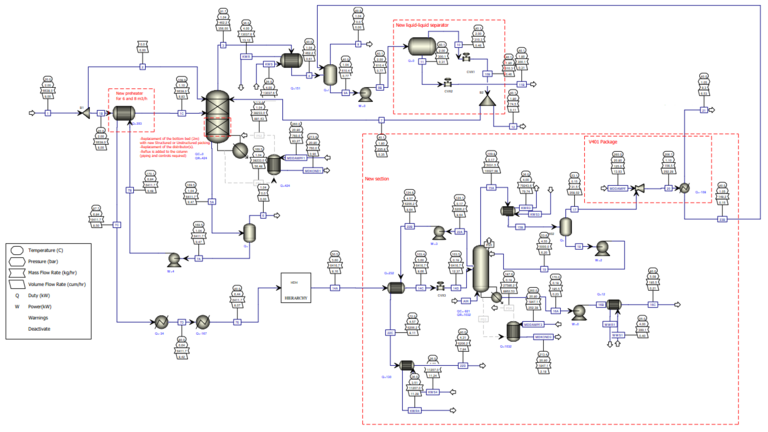

In the aforementioned plant and before its optimization, solvent was stripped out of a product stream in a column using steam. The vapors produced at the column’s head were then condensed with the use of cooling water and the concentrated solvent was returned to the process. The solution developed for its energy optimization, was the utilization of the condensation heat of the vapors for steam production purposes. For this purpose, vapors are fed to a plate heat exchanger for condensation.

Steam generation in this way takes place at a low pressure level. It can be reused then as stripping steam in the same plant with the use of ejectors. Most of the cooling water originally required to condense the vapors can now be saved. In addition, by using the natural circulation method, the use of a normally required feed pump could be avoided, leading therefore to additional energy savings.

Project execution

In close cooperation with the client, DMT ENCOS has developed and implemented this project through all typical project phases. In addition to process engineering concepts including the necessary process simulations, basic engineering and detail engineering have been also carried out. In line with the scope of the authority engineering, all necessary documents for the client were compiled, targeting the necessary approvals from the responsible authorities.

By developing inquiry specifications for the various equipment as well as the evaluation of corresponding offers from suppliers, the client could be supported throughout the whole procurement processes. The execution and commissioning of the plant modifications was finally supported by undertaking construction management activities and ensuring the necessary provision of updated documentation. The cost and deadline targets developed together with the client were secured by qualified project management.

Summary & Savings

What does the implementation of this energy optimization project mean for the client? First of all, the avoidable costs resulting from the upgrade of the utility systems for steam and cooling water, which was actually necessary for a planned capacity expansion of the process plant. In addition to these (one-off) investment costs, following ongoing savings could be reached:

- Approx. 60% of the steam required for the stripping process is now generated by waste heat

- Approx. 70% of the cooling water quantity required for the original head condensation of the vapors is eliminated

Calculate these ongoing savings.

We offer you the following Services:

- Energy efficiency studies / feasibility studies

- Process analyses

- Energy optimization

- Planning and implementation of optimization measures