Additional services

More efficiency for your projects - with our additional services.

EPCM

DMT ENCOS delivers expert engineering, procurement, and construction management services, adhering to the highest safety and quality standards in partnership with DMT. We tackle challenges head-on, managing every step from concept to handover, with a focus on customer satisfaction.

Basic Engineering

At DMT ENCOS, basic engineering involves a variety of activities, depending on the project and product scope. The required expertise in the plant's manufacturing process is key to planning efforts. Essential service steps are detailed below.

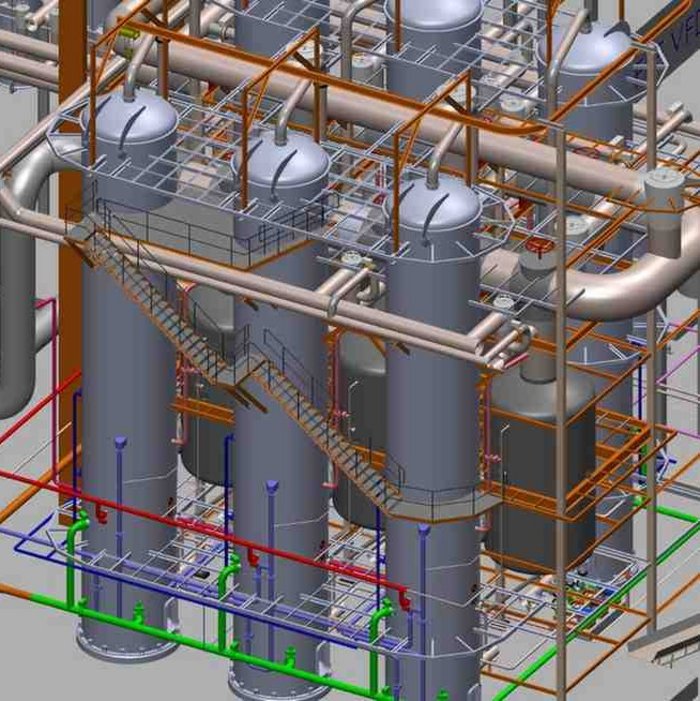

Detail Engineering

Our detailed engineering covers all relevant disciplines and planning steps up to process plant commissioning, including EPCM projects if needed.

Plant safety

The risk assessment, based on the Occupational Safety and Health Act and the Industrial Safety Ordinance, is the key tool for identifying hazards, evaluating risks, and determining protective measures.

Construction management

Construction management focuses on meeting key requirements during project implementation, ensuring compliance with safety, quality, deadlines, and costs. Leveraging years of experience and expertise, we aim for your complete satisfaction by setting high goals to meet your expectations.

Plant documentation

With growing demands for efficiency, shorter processing times, and quick access to technical documents, we deliver innovative solutions in plant documentation. At ENCOS, we specialize in advanced, smarter plant documentation, focusing on the following key areas.

EMSR

Modern measurement, control, and regulation technology (MSR) autonomously monitors and efficiently controls operating processes like air conditioning, ventilation, and heating systems, optimizing energy supply. The aim is to minimize energy costs and operating effort while ensuring reliability and cost-effectiveness

Process Engineering

Our projects in the field of process engineering are handled by our experienced engineers, with a focus on chemical plant engineering.

Process reliability

DMT ENCOS assists with safety issues across the entire lifecycle of a technical plant, focusing on a holistic approach that complies with legal and safety requirements, especially in the chemical, oil, and gas industries.

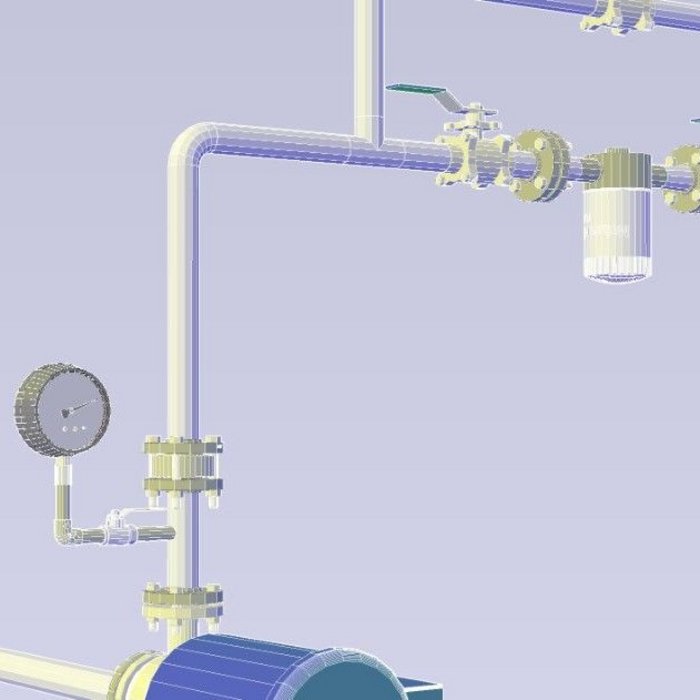

Piping

DMT ENCOS develops detailed piping plans for diverse industries, from integrating into existing plants during expansions to fully planning piping for new process plants with significant investment costs.

Feasibility studies

We support our customers from the early stages of idea development with core competencies that have been established through decades of experience in the implementation of a wide range of process engineering processes.

Mechanical Engineering

DMT ENCOS does not act as an equipment manufacturer and therefore does not create manufacturing drawings. This highlights the importance of mechanical engineering steps during procurement: reviewing, commenting on, and approving production drawings, as well as coordinating tests with installation planning and piping

Civil Engineering

DMT ENCOS is pleased to offer comprehensive services from a single source if desired. However, if you already collaborate with established civil engineering partners, we are equally happy to support you with related matters. We assess each case individually to determine the most solution-oriented .

Authority Engineering

We offer you government engineering and expert planning from a single source.

Project management

We initiate, plan, manage, and monitor our projects in a targeted manner, and implement them efficiently.

Operator obligations

DMT ENCOS, together with TÜV NORD, specializes in operator obligation analysis to uncover weaknesses. We offer comprehensive solutions for occupational safety, environmental protection, and plant safety using diverse methodologies.