Chemical industry

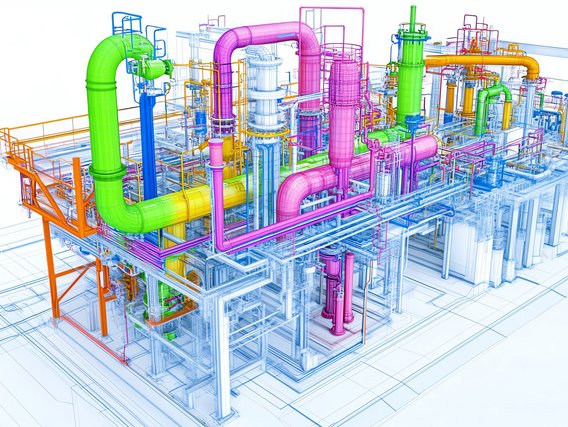

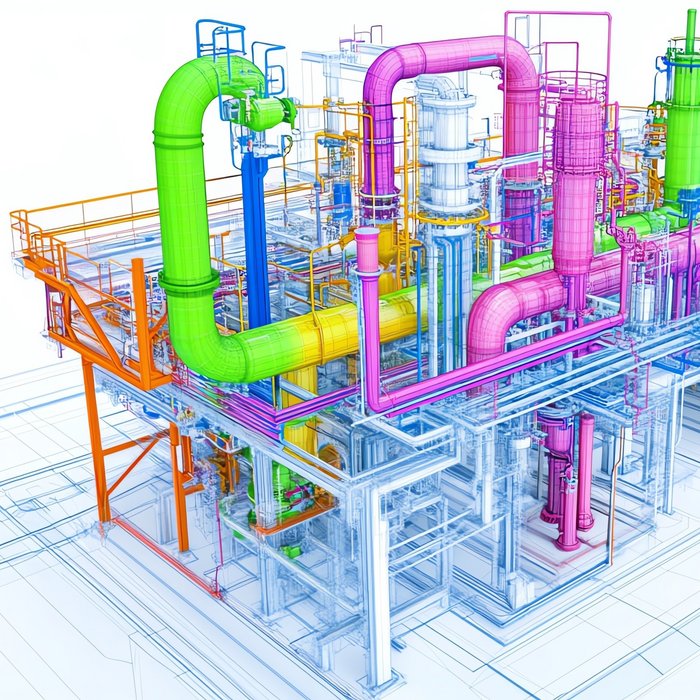

Safe realization of complex processes

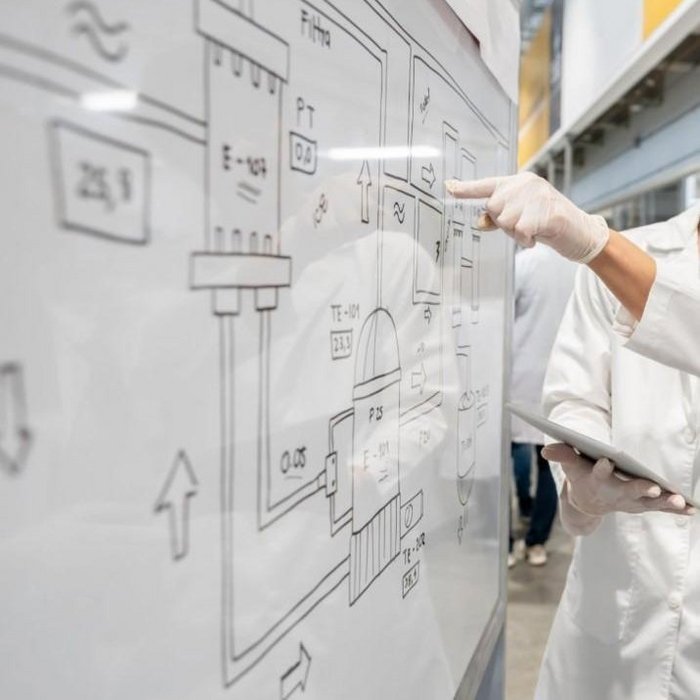

The chemical industry, with its preliminary and intermediate products, forms the backbone of numerous sectors. As an EPCM service provider, we provide support the industry with interdisciplinary engineering that meets the highest standards of safety, efficiency and flexibility.

Our services in the chemical industry:

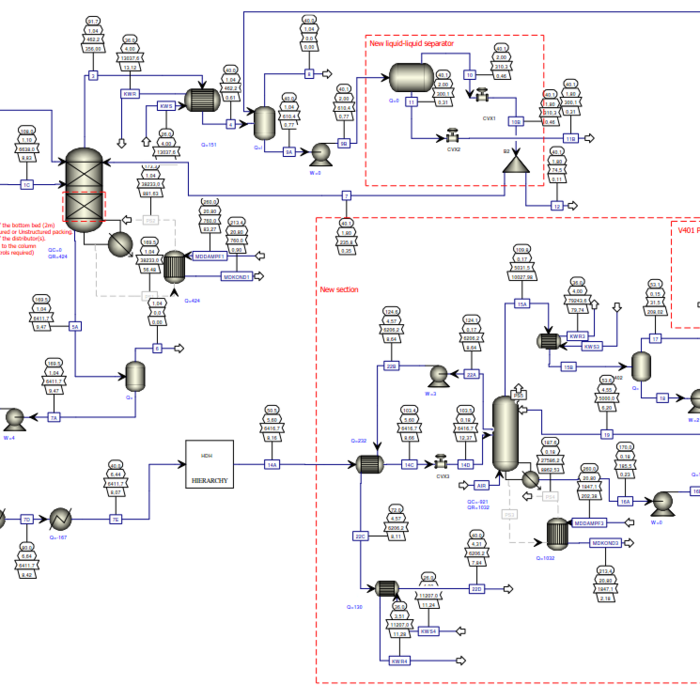

Integrated engineering: process engineering, EI&C, plant engineering, design, safety engineering and project management

Project support: from feasibility studies and BImSchG approvals to commissioning

Plant safety: Implementation of explosion protection, HAZOP and risk analyses

Efficiency & sustainability: Optimization of processes, energy use and material cycles

Project focus: Amine plants, kerosene plants, plants with organic chemicals, high-pressure hydrogenation plants, ethylene oxide plants, catalyst carrier systems, aluminum oxide plants, microreactor engineering