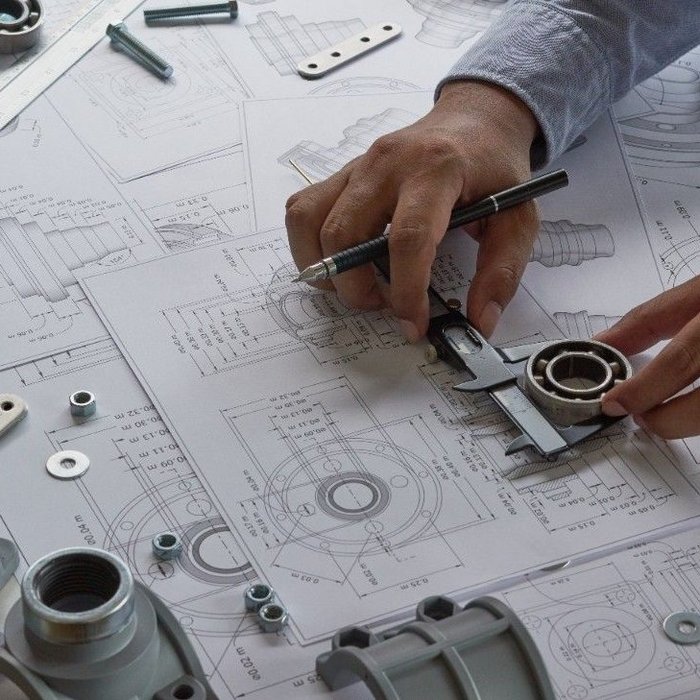

- Piping design at DMT ENCOS: efficiency, flexibility and quality

DMT ENCOS creates detailed piping plans for a wide range of industries. Our project portfolio ranges from selective integration into existing plants as part of expansions and modifications to the complete pipework equipment of new process plants with investment costs in the double-digit million euro range. We always regard pipework planning as an integral part of the overall plant design, regardless of whether ENCOS acts as a general planner or concentrates on detailed pipework planning.

- Our strengths in piping design

Piping design at DMT ENCOS is characterised by the following features:

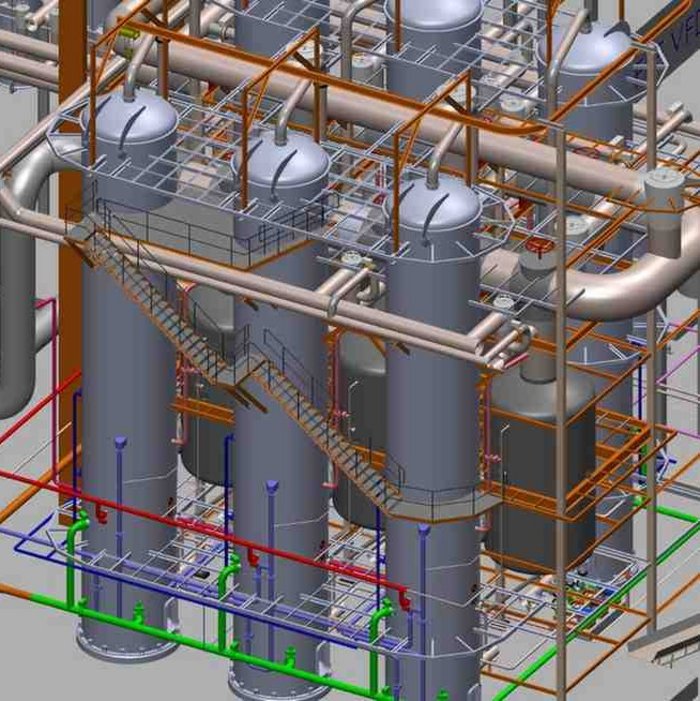

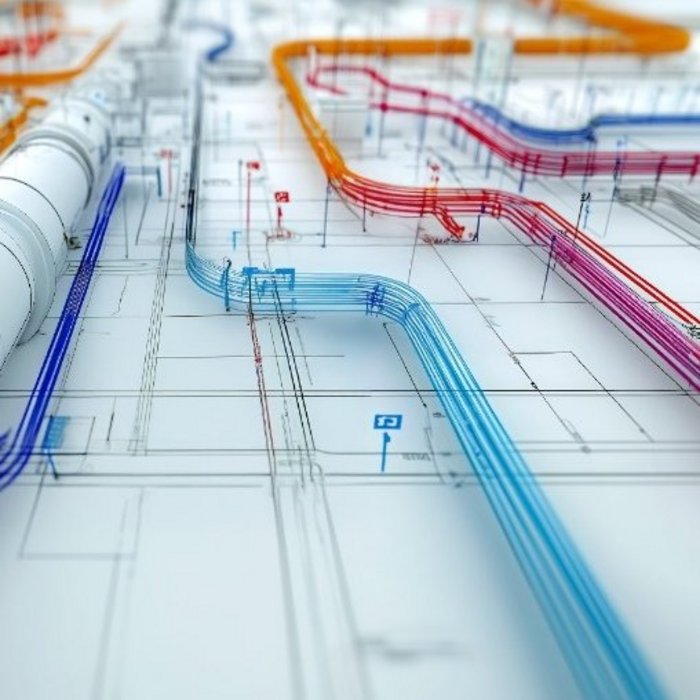

- Use of 3D design tools: We use advanced software solutions such as PDMS, Bentley Autoplant and AutoCAD Plant3D to create precise and efficient piping designs. These tools enable detailed visualisation and optimisation of the piping layout, resulting in improved planning reliability and efficiency. Thanks to 3D modelling, potential conflicts can be identified and resolved at an early stage, which shortens construction time and reduces costs.

- Use of 3D measurement technology: We use 3D laser scanners to record the existing situation of existing systems. This technology enables precise measurement and documentation of the current situation, which makes it easier to integrate new pipework into existing systems and increases planning reliability. The precise recording of the current situation minimises the risk of planning errors and ensures seamless adaptation to existing structures.

- Deployment of flexible teams: Our teams have interface expertise in process engineering and pipe system statics, which ensures seamless integration of pipework planning into the overall system design. This interdisciplinary collaboration enables us to respond flexibly to the specific requirements of each project and develop customised solutions. Our experts work closely with other disciplines to ensure that all aspects of planning are optimally harmonised.

- Advantages of our pipeline planning

By combining state-of-the-art technology and interdisciplinary expertise, we offer pipeline planning that is not only efficient and flexible, but also meets the highest quality standards. Our approach ensures that your projects are completed on time and within budget, while maximising operational safety and efficiency. We emphasise compliance with all relevant standards and regulations to ensure the safety and reliability of your facilities.

- Customised solutions for complex challenges

Every project brings its own challenges, whether due to specific technical requirements, space restrictions or special safety requirements. DMT ENCOS specialises in developing individual solutions that are precisely tailored to your needs. We offer comprehensive advice and support in all phases of the project, from concept development and detailed planning through to implementation and commissioning.

- Sustainability and future-proofing

In today's world, it is more important than ever to develop sustainable and future-proof solutions. DMT ENCOS is committed to integrating environmentally friendly technologies and processes into pipework planning. We are constantly working to improve energy efficiency and minimise the environmental footprint of your systems. Our planning takes into account not only current requirements, but also future developments and trends to safeguard your investments in the long term.