Process engineering at DMT ENCOS: expertise in chemical plant engineering

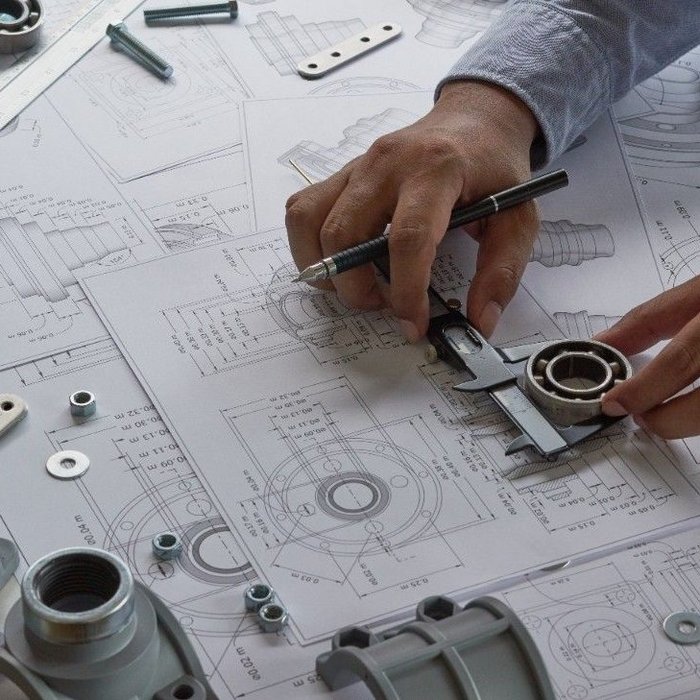

Our process engineering projects are managed by experienced engineers who specialise in chemical plant engineering. We offer comprehensive services aimed at making your plants efficient and safe. Our approach combines technical expertise with innovative solutions to fulfil the specific requirements of your projects.

Our focus

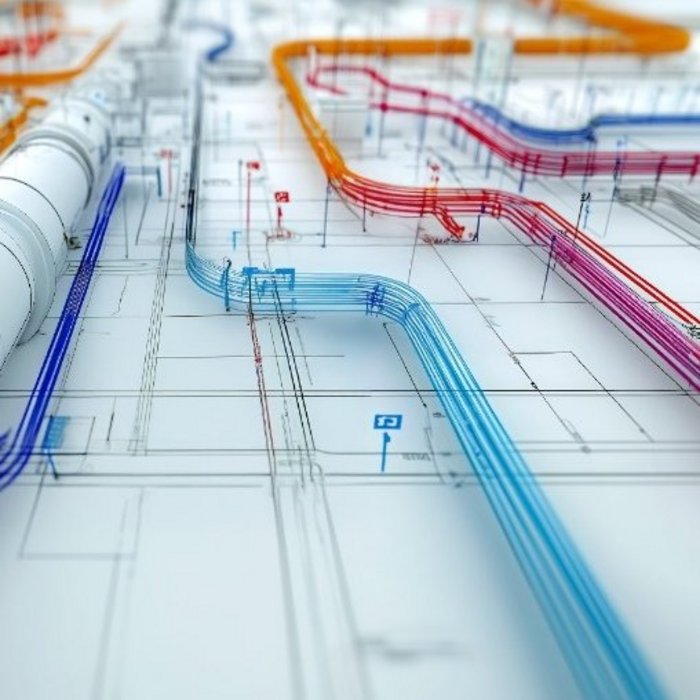

- Development of process flow diagrams: We create detailed process flow diagrams that clearly show the processes and interactions within your plant. These diagrams are crucial for planning and optimising processes and serve as the basis for further technical designs. They help to visualise complex processes and enable precise communication between the various project participants.

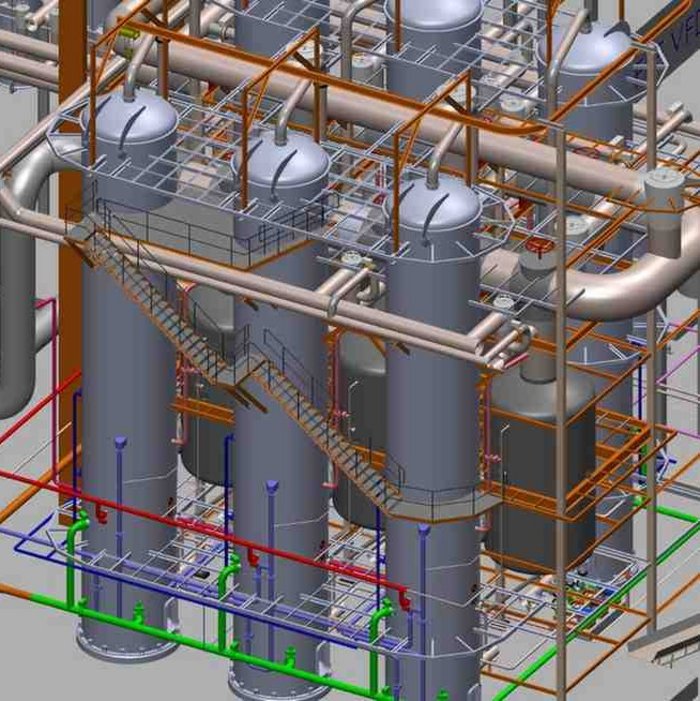

- Process engineering design of the system components: Our engineers carry out the process engineering design of the system components to ensure that all parts are optimally matched to each other. This includes the selection and dimensioning of reactors, heat exchangers, pumps and other critical components. We take into account both the thermodynamic and kinetic aspects of the processes to ensure maximum efficiency and safety.

- Process engineering arrangement of equipment and machinery: We plan the arrangement of equipment and machinery within your plant to ensure efficient and safe operation. This planning takes into account both the spatial conditions and the process control requirements. Our engineers work closely with you to develop an optimal layout design that both minimises operating costs and maximises ease of maintenance.

- HAZOP studies and much more: Our HAZOP studies (Hazard and Operability Studies) are an essential part of our safety analyses. They help to identify potential hazards at an early stage and develop suitable risk minimisation measures. These studies are carried out by interdisciplinary teams that bring in different perspectives and expertise to develop comprehensive safety solutions. In addition, we offer a variety of other services tailored to the specific needs of your projects, such as conducting SIL (Safety Integrity Level) analyses and implementing safety management systems.

Further details on our services

For more information on our plant design and EPCM (Engineering, Procurement, Construction Management) services, please visit our "Plant Design - EPCM" section. There you will find comprehensive information on our services and how we can successfully realise your projects. Our EPCM services cover the entire spectrum from concept development and detailed design to construction supervision and commissioning to ensure that your projects are completed on time and within budget.

Successful projects and case studies

DMT ENCOS has delivered a wide range of successful process engineering projects that have significantly improved our clients' efficiency and productivity. Our case studies show how we have achieved outstanding results through innovative approaches and interdisciplinary collaboration. From the optimisation of existing plants to the development of new processes, we have delivered tailor-made solutions that meet the specific requirements of our customers.

Innovations and future prospects

DMT ENCOS strives to continuously develop innovative solutions that meet the changing needs of the chemical industry. We invest in research and development to explore new technologies and processes that further improve the efficiency and sustainability of our chemical processes. Our future prospects include the integration of digital technologies and automation to optimise process control and further reduce operating costs. This includes the development of intelligent control systems that enable real-time monitoring and adjustment of process conditions.