What is Advanced Process Control?

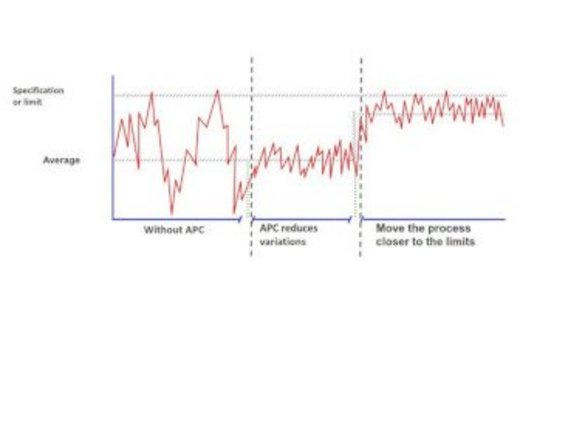

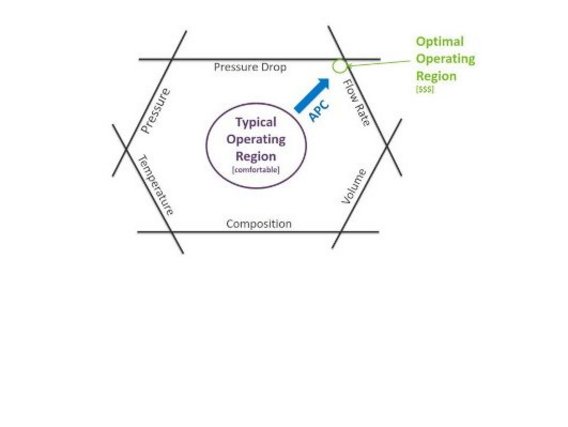

APC is a model-based predictive control technique that calculates the optimal operating point and controls the process-dependent variables (e.g. conversion and yield) by controlling the process values (e.g. material flows, pressures, temperatures).

The APC controller thus represents an efficient and experienced operator who precisely understands the plant dynamics based on historical data, derives predictions about the plant behavior from this, and thus controls the plant at its optimum operating level.

And this 24/7 with uninterrupted attention.