DMT ENCOS Mechanical Separation Processes

The mechanical separation processes comprise separation, classification and sorting processes and are essentially divided into the following main Groups: Density separation process, filtration process, depth filtration and surface filtration.

How does DMT ENCOS use mechanical separation processes in plant design?

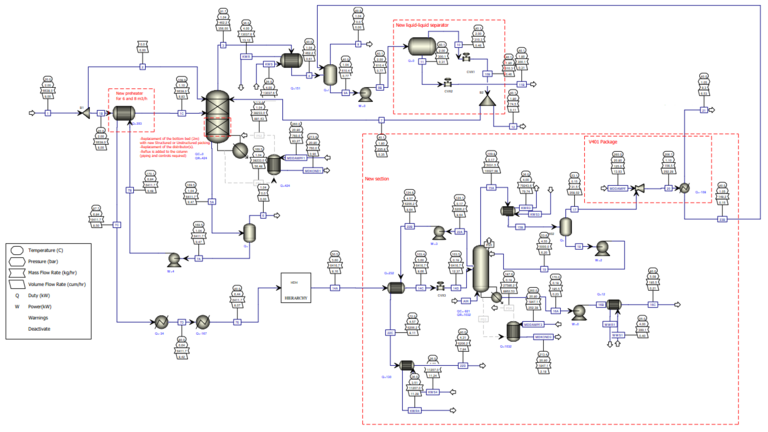

DMT ENCOS mainly designs process plants, which are dominated by basic thermal operations, therefore the basic mechanical operations concentrate on specific tasks such as:

- Separation of solids from reaction mixtures by filtration units, membrane separation units, separators or hydrocyclones

- Product gas separation after two-phase reactors or in flare systems through phase separation vessels

- Liquid-liquid separation in OvHD systems for azeotropic distillation using three-phase separation vessels

- Dewatering of fuel tanks using coalescing separators

- Droplet separation from gas streams with demisters and plate packs

Especially for the design of separation vessels DMT ENCOS uses self-developed programming solutions (tools), which allow the dimensioning of two- and three-phase separators with and without inserts of plate packs or droplet separators (demister).

DMT ENCOS also has its own calculation tools for the design of hydrocyclones. Filtration units for solid/liquid separation with specific or rotating installations for cleaning or with media connection for backwashing processes are specified according to process engineering and mechanical requirements in order to ultimately be procured as package units from specialized vendors.

Membrane separators are used in a similar manner. Most recently, filter systems for the large-scale separation of dusty products from the drying air flow were also successfully planned as external package units.

Please feel free to discuss your task in more detail with our specialist departments. We look forward to getting to know you personally.

We are looking forward to your inquiry.

Buxtehuder Straße 29

D-21073 Hamburg

Tel.: +49 40 751158-0

Fax: +49 40 751158-30

info@encos.de