For more Energy Efficiency and economy in the Process Industry

How can I reduce my primary energy consumption up to 40%?

Thermal energy very often accounts for a considerable share of a company's total energy requirements. The process-related heat recovery is the central element for increasing energy efficiency, in order to significantly reduce energy costs through multiple use of process heat and to remove components that may no longer be efficient and relevant to the system. With each heat recovery, however, larger financial investments are also required, such as the planning and installation of new heat exchangers and piping systems.

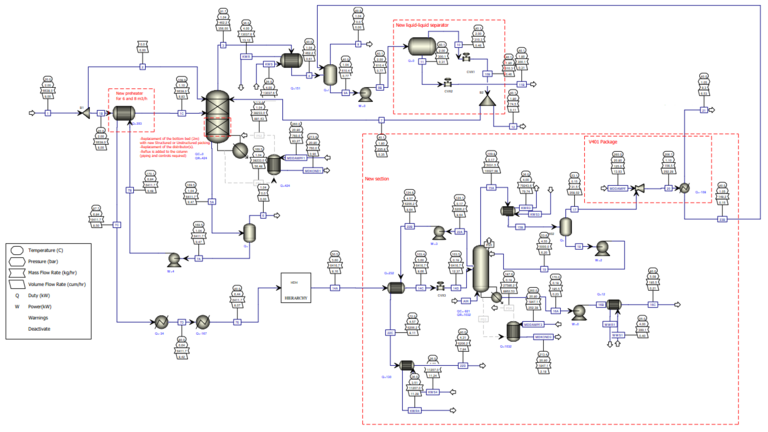

Through a Linnhoff analysis, also called Pinch Point analysis, DMT ENCOS engineers find the optimal combination of the different energy flows and their usability, with the objective of a minimum total amount of investment and energy costs. This means that sensible measures for heat recovery and improved energy supply can also be derived at a single location as part of strategic planning. Pinch point analysis is also a valuable instrument for the design of new plants and their process engineering design in order to optimally exploit energy efficiency potentials and thus contribute to a reduction in primary energy requirements of up to 40%.

Reduce energy requirements and thus costs step by step.

We guide you step by step to your energy saving goal:

- Holistic analysis of industrial areas with continuous batch processes

- Process analyses with variable operating parameters

- Determination of the meaningful and absolute saving potential Variant studies - Feasibility analyses

- Optimization of energy supply systems and technical processes that have become inefficient in the meantime

- Integration of more efficient technical solutions into your overall supply concept

The analysis answers the following questions:

- How much energy would be required if a fully optimized sub-process or overall process were available?

- How can the existing energy supply be optimally adapted and, if necessary, expanded?

- Where is the optimum for investment and energy costs? How can I achieve the optimum state within my processes?

We are looking forward to your inquiry.

Buxtehuder Straße 29

D-21073 Hamburg

Tel.: +49 40 751158-0

Fax: +49 40 751158-30

info@encos.de